Introduction

For indoor growers, increasing indoor heat dissipation and maintaining indoor temperature are important tasks, and temperature changes are crucial for plant growth. The extensive use of air cooling lighting systems greatly improves indoor heat dissipation, allowing growers to use higher intensity plant lights. The large-scale use of air-cooled lighting systems has also accelerated the promotion of indoor planting.

For indoor growers, air-cooled lighting systems have become an important tool, and understanding air-cooled lighting systems can optimize the growth environment of indoor crops.

What is Air Cooled Lighting?

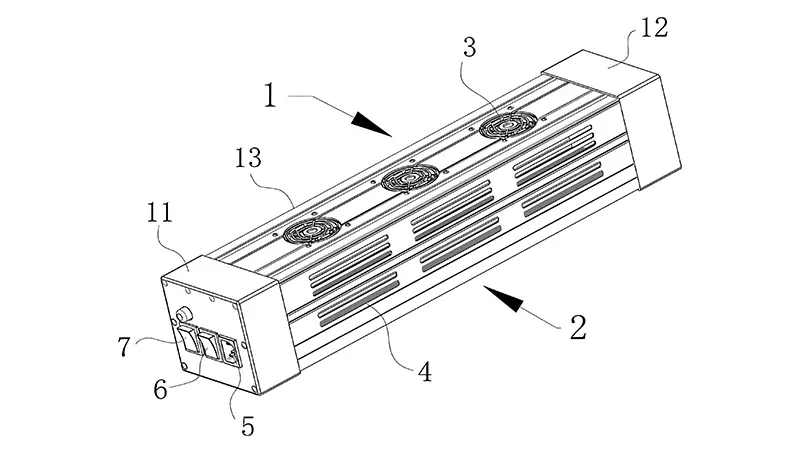

Air cooled lighting is a lighting device that also has an air cooling system. This air cooling system accelerates air flow, which can dissipate the heat generated by the grow linght through the circulation of air. Compared to general lighting, air-cooled lighting has better heat dissipation, which can reduce the luminous efficiency of growth lamps, increase their lifespan, and reduce energy consumption.

Basic Principle of Air Cooled Lighting Systems Work

The air-cooled lighting system includes an airtight channel and a fan. Fans will accelerate air circulation, and cold air will flow through the growth lamp, taking away heat. Generally, indoor planting areas have exhaust systems, which will timely dissipate this heat to the outside without causing overheating to the plants inside.

Understanding Air Cooled Lighting Systems

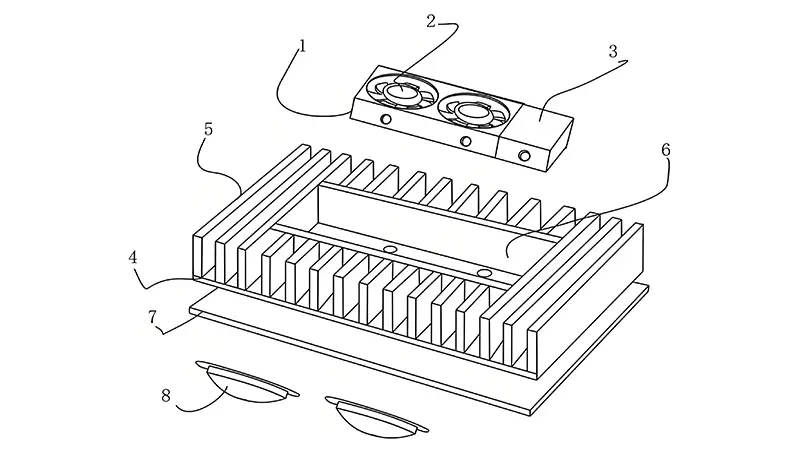

The core of an air-cooled lighting system is an air circulation system that can carry heat out through the air, which can promptly dissipate the heat. Below, we will analyze and disassemble this system:

Air Cooled Hood/Reflector: A type of shell with good thermal conductivity, which has a dedicated channel for cold air to pass through. Through this channel, cold air can better remove heat.

Ducting: This is a flexible pipe with a diameter of 6 inches or more, through which hot air can be discharged to a designated location.

Inline Fan: The fan is the power unit of this system, and the power source for air circulation is this fan.

Carbon Filter: This is a filtering device that can remove indoor environmental odors.

Light Bulb: The light bulb is the light source of this system.

Benefits of Air Cooled Lighting

Temperature Control

The cold air lighting system can effectively reduce the heat of the light source and prevent it from overheating. Reducing the heat of the grow light can greatly increase its lifespan.

Energy Efficiency

Air cool lighting comes with a built-in light source cooling device, eliminating the need for users to purchase additional cooling equipment. Moreover, reducing heat can effectively decrease system resistance and reduce power consumption.

Closer Light Placement

The heat of the light source is effectively dissipated, which can make the light source more in contact with plants without burning them. The proximity of light sources to plants can enable them to better receive light and increase the utilization rate of light sources.

Extended Bulb Lifespan

The temperature of air-cooled lighting bulbs is relatively lower, which can increase the lifespan of the bulbs and slow down the aging of other related components.

Improved Environmental Control

- Indoor temperature distribution is more balanced

- Increase indoor air circulation for better distribution of carbon dioxide

- Plant growth environment is more stable

Cost Benefits

- Lower monthly utility bills

- Equipment aging slows down and replacement frequency decreases

- Increase light source utilization and improve crop yield

- Reduce the loss caused by the impact of heat on plant growth

How to Avoid Common Mistakes

The Power of The Fan is Too Low

Growers often overlook the ventilation needs of air-cooled lighting and choose fans with low prices and low power when selecting them. Insufficient power of the fan can result in insufficient heat dissipation for cold air lighting, which cannot effectively dissipate heat and achieve the desired effect for growers. This will shorten the lifespan of the growth lamp and may also burn crops. When choosing a fan, choose one with high power to achieve the desired effect.

Poor Ducting Layout

The wiring method of the pipeline can affect the cooling efficiency of the air cooling system. When wiring pipelines, try to avoid bends and nodules as much as possible. Bending and nodules can slow down air circulation and reduce the efficiency of the air cooling system. When wiring pipelines, it is important to plan carefully and increase the power of the air cooling system.

Improper Sealing

Air leakage can also reduce the efficiency of air-cooled lighting. Air leakage will allow air to circulate through the leaking area rather than through pipes. Leakage can cause insufficient circulation between the cold air in the air-cooled system and the hot air around the light source. After laying out the pipeline, it is necessary to carefully check the airtightness of the air cooling system to ensure that the entire system is in good condition.

Inadequate Ventilation

Many growers focus on the heat dissipation and air exchange of growth lamps while neglecting the ventilation of indoor environments. If the entire indoor ventilation is poor, it will increase the temperature of the entire indoor environment and reduce the carbon dioxide content, which is not conducive to plant photosynthesis and will affect plant growth. Maintain ventilation in the indoor environment to promote plant growth.

Regular Maintenance

Wind cooled lighting requires regular maintenance and upkeep by growers. Lack of maintenance and upkeep can lead to the accumulation of many small problems in air-cooled lighting systems, which can affect the efficiency of the entire system and accumulate over time, turning small problems into answer questions. Active maintenance of air-cooled lighting can reduce equipment replacement and lower operating costs.

Cost Considerations

Initial Investment

The initial cost of air-cooled systems is relatively higher than that of traditional systems, requiring the purchase of components such as hoods, fans, pipes, as well as controllers and temperature monitoring equipment. Although air-cooled lighting is more expensive, it can increase the efficiency and lifespan of growth lamps. In the short term, the cost of cold air lighting is higher, but as time goes on, the more upfront costs are amortized, making the air cooling system more cost-effective.

Operating Costs

The operating costs of growth lamps mainly include electricity bills and the cost of replacing accessories. Compared to ordinary growth lamps, air-cooled lighting has higher efficiency, lower power consumption, and overall energy savings. Air cooled lighting comes with a cooling function. Ordinary growth lamps require additional cooling equipment or cooling needs to be turned off when working for a long time, while air cooled lighting can work for a long time without additional cooling equipment. Overall, air-cool lighting will reduce the cost of electricity for growers.

Maintenance Expenses

Regular maintenance costs should be factored into your budget planning. This includes:

- Quarterly filter replacements

- Annual bulb replacements

- Periodic duct cleaning

- Fan servicing

- Seal replacement

- Hood cleaning supplies

Hidden Costs to Consider

- Insurance implications for better safety systems

- Potential electrical upgrades needed

- Back-up equipment for emergencies

- Professional installation if needed

- Monitoring system expenses

- Controller replacements

Scaling Considerations

As your operation grows, costs can be optimized through:

- Bulk purchasing of components

- More efficient multi-light configurations

- Shared ventilation systems

- Automated control systems

- Improved space utilization

Cost-Saving Tips

- Buy quality components first time

- Regular maintenance prevents expensive repairs

- Monitor efficiency to spot problems early

- Consider energy-efficient fan models

- Plan system layout carefully to minimize materials needed

- Take advantage of natural cooling when possible

Conclusion

Air cooled lighting systems represent a significant advancement in indoor growing technology, offering growers unprecedented control over their environment. Through efficient heat management, these systems enable closer light placement, reduced cooling costs, and improved plant health. The ability to maintain optimal growing conditions while maximizing light intensity has made air cooled lighting an essential tool for serious growers of all scales.