The power factor, which measures the efficiency of electricity use, is the ratio of active power to perceived power. Most LED lights boast a power factor of “>0.9.” Is this “0.9” high enough for LED lights? Is the power factor of LED lights different from that of some other devices? You will know more about how to evaluate LED lights by their power factor after reading this passage.

What is the LED power factor?

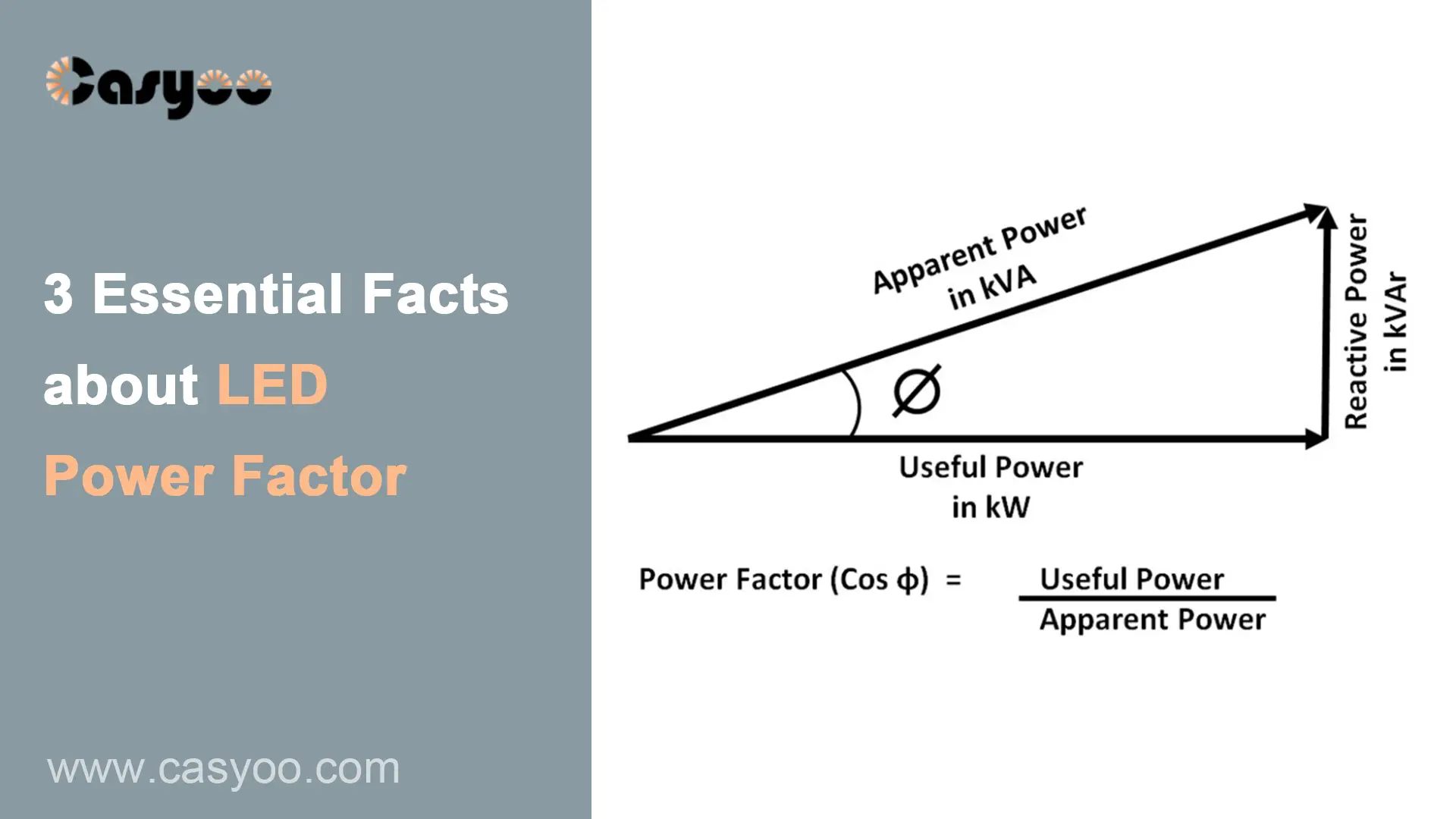

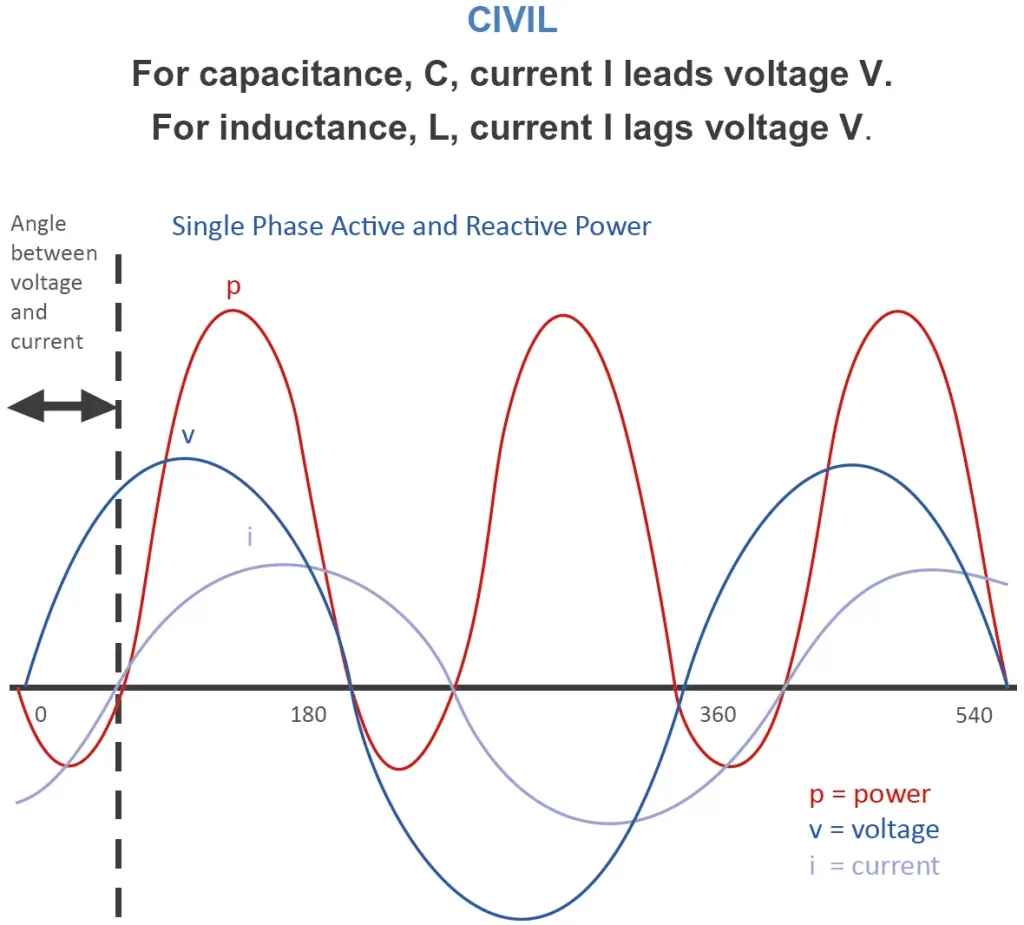

For devices using alternating current, the power factor is a crucial parameter. Voltage and current in a completely resistive load are in the same phase. However, for inductive or capacitive loads, there’s a phase angle (φ) between them due to electromagnetic effects. The power factor (PF) is calculated as PF=VIcos(ϕ), and closer to 1 is better, indicating optimal power utilization.

Traditional power factor calculation suits linear elements but falls short for nonlinear elements like LED lights. When using the main power, LED lights require rectifiers to convert AC to DC. And then there will be a capacitor to filter spurious components like the harmonics and make the current and voltage more stable. As we mentioned before, once there is a capacitor in the circuit, the power factor cannot be 1. But this capacitor is necessary because, without it, the fluctuating voltage and current will make LED lights flicker. So you will always find the LED lights have a power factor of “>0.9.” As per the ERP (energy-related products) standard, LED lights over 25 W should maintain a power factor above 0.9.

Why is the LED power factor important?

- Making the current lower: For the same amount of electricity, lights with a low power factor will need a higher current to work normally. The reason is that the low power factor makes them produce too much reactive power. High current will lead to more heat generation, unsafe circuit, voltage drop, and shorten the lifespan of LED lights.

- Cut the costs: The low power factor in the lights increases energy waste and electricity consumption, resulting in higher bills. What’s more, most local power departments will penalize devices with subpar power factor, especially for street lights. Low power factor devices waste more utility power and violate the utility grid with their unstable waveform.

How to compensate for the low power factor?

The technique that is used to compensate for low power factor is called a PFC (Power Factor Correction) circuit, and there are two types of it: active PFC and passive PFC.

Active PFC circuits use electronic devices (usually power switching devices, such as MOSFETs) to actively adjust the waveform of the input current to synchronize it with the input voltage, thereby improving the power factor.

Passive PFC mainly adjusts the current waveform by using passive components (such as inductors and capacitors) to improve the power factor.

In LED lighting systems, active PFC circuits are usually used to ensure efficient energy utilization and a high power factor. This enhances the system’s overall performance. PFC circuits are usually integrated into LED drivers to ensure that LED lamps have minimal impact on the grid when working. Therefore, even though some lights don’t have a high power factor, manufacturers should design the circuit to improve it so that it is up to standard.

Conclusions

Due to their nonlinear nature, LED lights have distinct power factor characteristics. They need capacitors to stabilize the current after current conversion, and because of this, the highest power factor of LED lights can only be infinitely close to 1. Quality LED lights should have a power factor exceeding 0.9. For those with low power factor, manufacturers should find a way to compensate. In this way, these lights will not waste energy or increase the costs of users. All the LED lights from Casyoo have a power factor which is above 0.9, ensuring their high efficiency while working. Contact us for different types of efficient LED lights!